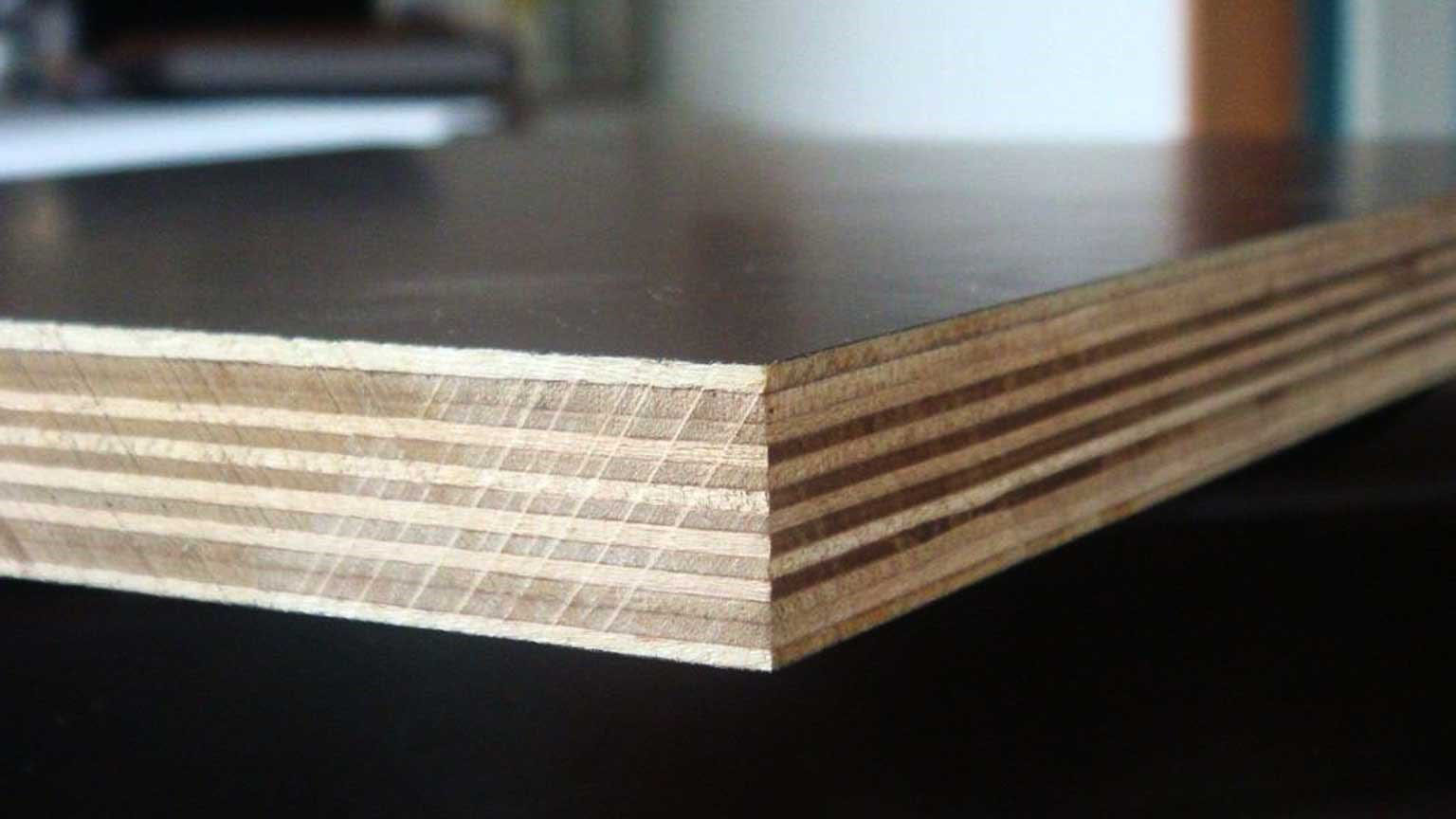

BWP stands for "Boiling Water Proof." It is a classification of plywood commonly used in construction and furniture-making. BWP plywood is designed to be highly resistant to water and moisture, making it suitable for applications where the wood may be exposed to wet or humid conditions.

The term "IS 710" refers to a specific Indian Standard (IS) grade for plywood. IS 710 is a code that sets standards for the quality and specifications of marine or boiling water-proof (BWP) plywood in India.

BWP plywood is manufactured with special adhesive resins that make it highly resistant to water and moisture. This type of plywood can withstand exposure to boiling water for extended periods without delamination or damage.

BWP plywood typically meets strict quality standards and undergoes rigorous testing to ensure its water resistance. It is often certified by relevant authorities or standards organizations to ensure it meets the specified criteria.

BWP plywood is commonly used in construction for applications such as making outdoor furniture, doors, window frames, and other structures that may be exposed to rain or moisture. It is also used for making formwork in concrete construction.

BWP plywood is frequently used in the fabrication of kitchen cabinets, bathroom cabinets, and other furniture where resistance to water and humidity is essential. It's important to note that BWP plywood is typically more expensive than standard plywood grades due to its specialized water-resistant properties.

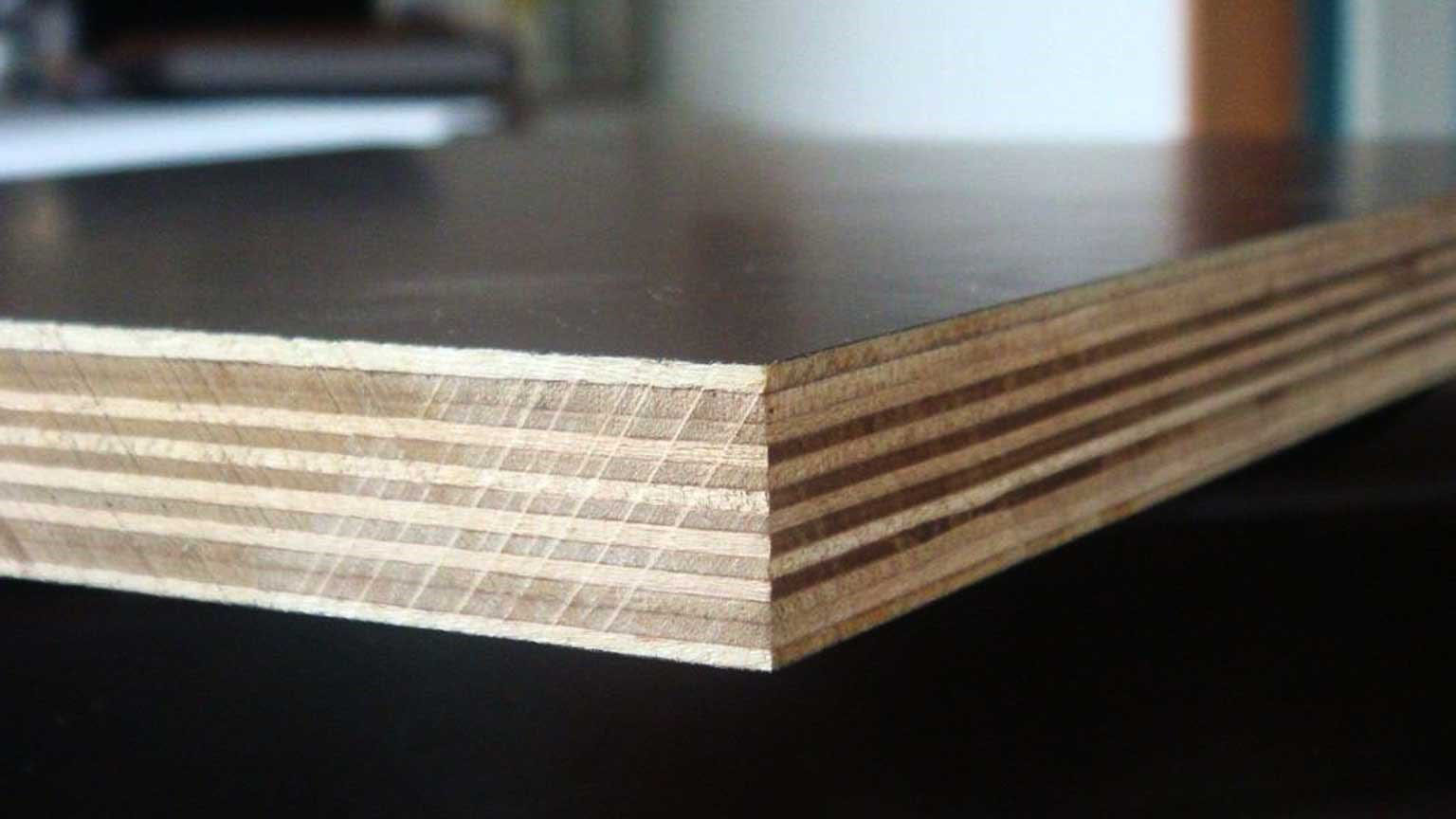

BWR plywood is manufactured using a specific type of adhesive that is resistant to water and moisture. This adhesive helps prevent the plywood from delaminating or falling apart when it gets wet. The plywood sheets are typically made from high-quality hardwood veneers, which also contribute to its strength and durability.

This type of plywood is specially designed for use in environments where it may be exposed to moisture or water. It is often used in applications that require water resistance, such as in the construction of furniture for bathrooms and kitchens

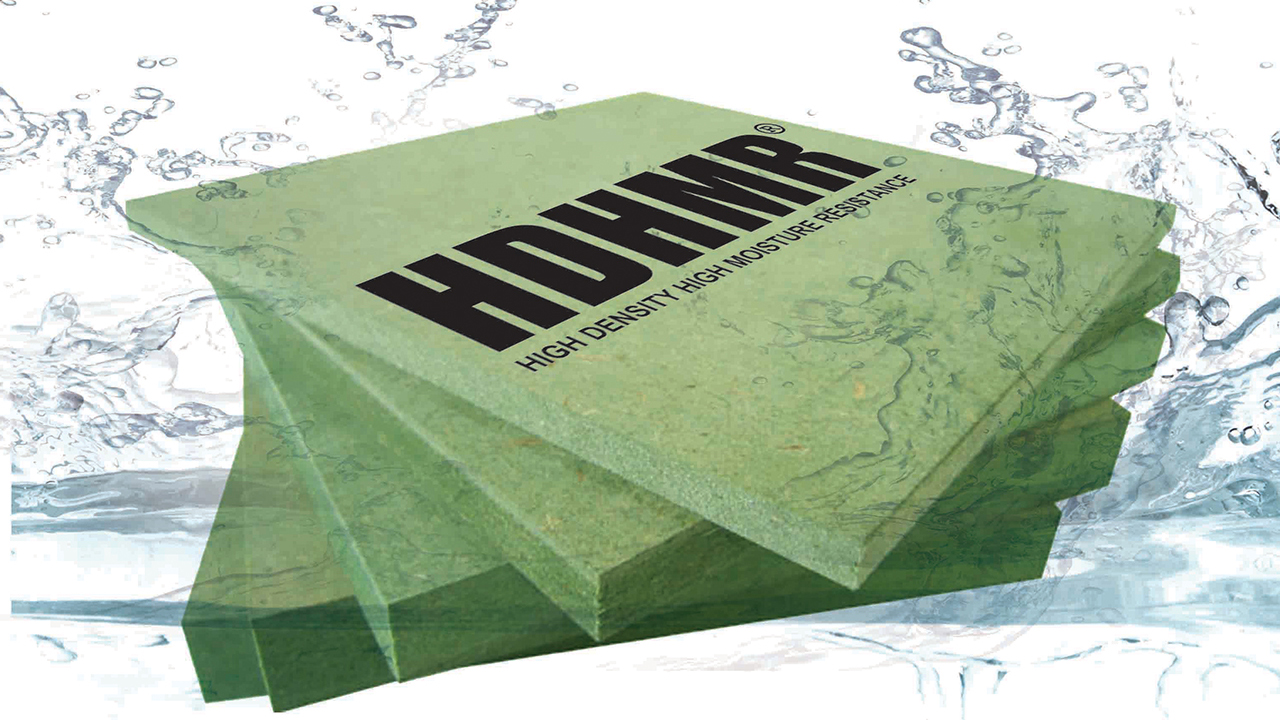

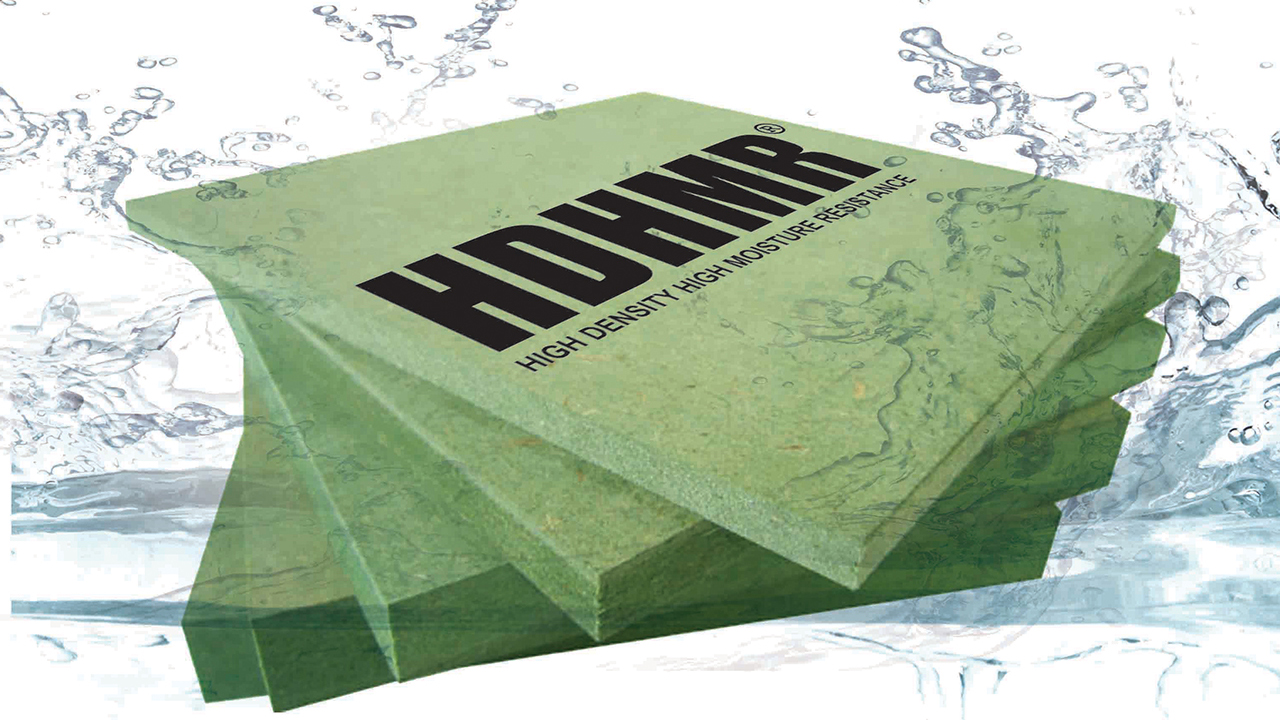

HDHMR stands for "High-Density High Moisture Resistance" plywood. It is a type of plywood designed to have high resistance to moisture, making it suitable for applications in wet and humid environments. HDHMR plywood is often used in interior and exterior construction, particularly in areas where the wood may come into contact with moisture, such as kitchens, bathrooms, and furniture that may be exposed to humidity.

High Density: HDHMR plywood is denser than standard plywood, making it more robust and durable. This density is achieved through a special manufacturing process that involves using high-pressure compression.

Smooth Surface: HDHMR plywood typically has a smooth and even surface, which makes it ideal for finishing with laminates, veneers, or paints. This results in an attractive and durable surface finish for various applications.

Versatility: HDHMR plywood can be used in a wide range of applications, including kitchen cabinets, bathroom vanities, shelving, furniture, and structural elements in buildings.

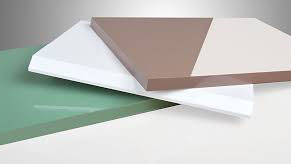

MDF stands for Medium-Density Fibreboard. It is an engineered wood product that is commonly used in a variety of applications in construction and woodworking. MDF is made by breaking down wood fibres, combining them with wax and resin, and then compressing them at high temperatures and pressures to create dense, smooth panels of consistent thickness.

MDF is a versatile material that can be easily cut, routed, and shaped into various forms and sizes. It is commonly used for creating intricate designs, carvings, and mouldings due to its ability to hold intricate details.

Paint ability: MDF takes paint very well. Its smooth surface is ideal for achieving a high-quality, even finish when painted. This makes it a popular choice for furniture and cabinet construction.

Cost-Effective: MDF is often more affordable than solid wood or other engineered wood products, making it a cost-effective choice for many applications.

MDF is widely used in the construction of furniture, cabinets, doors, mouldings, and decorative wall panels. It is a popular choice for many interior design and woodworking projects due to its versatility and affordability.

We are ready to help you